Solution

-

-

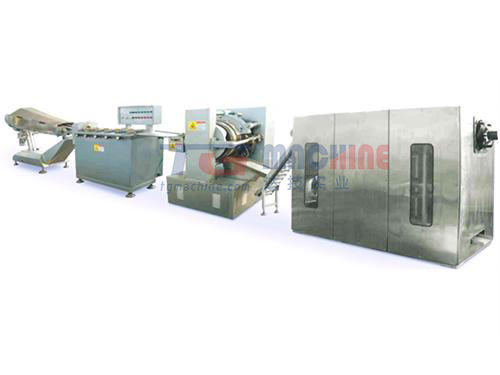

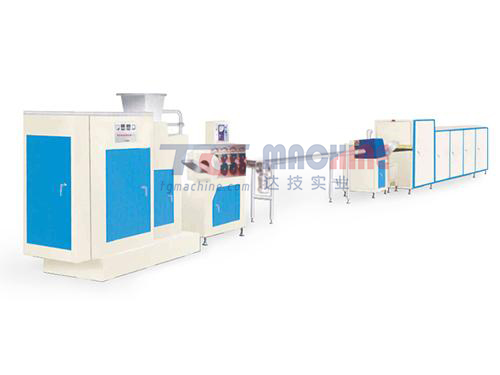

- Hard Candy Production Line

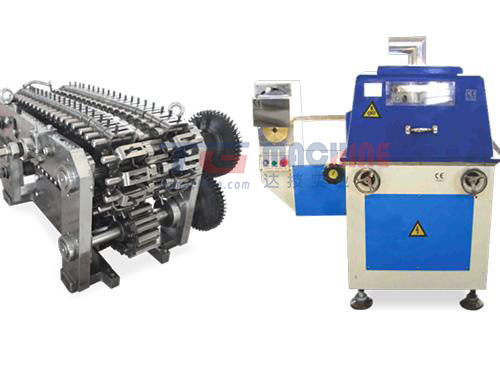

The hard candy production lines manufactured by TG Machine are designed to produce various hard candy types, including one-color, two-color, three-color, and four-color hard candy. Through simple configuration adjustments, our hard candy production line can be used to make multi component candy, striped candy, layered candy, filled candy, and much more.

These candy lines produce high-quality candies with high-efficiency. They are largely automated, requiring only a few workers to operate the whole production line.

-

-

- Gummy Candy Production Line

Gummy Candy is available in a multitude of flavors and is manufactured in a variety of rectangular or irregular shapes. TG Machine’s Gummy Candy Production Lineis customizable to meet specific customer requirements, and we also offer different mold types for the production of a diverse array of candy types.

-

-

- Sucker Production Line

TG Machine has extensive experience in the design and manufacturing of sucker production line. This production line allows you to easily produce different sucker types and shapes, including striped suckers, filled suckers, double color suckers, flat suckers, and more. By changing the configurations, the sucker production line is ideal for the production of countless sucker types, limited only by your creativity.

-

-

- Chewy Gum Production Line

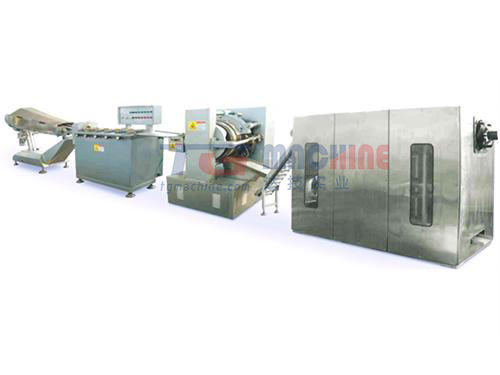

Chewing gum is comprised of a natural gum, syrup and other additives for flavor, and thus, requires a variety of different equipment during production. TG Machine manufactures a variety of chewing gum production lines for the production of chewing gum in a variety of different shapes.

Our fully automatic chewing gum production line also improves factory productivity and lowers labor costs.

-

-

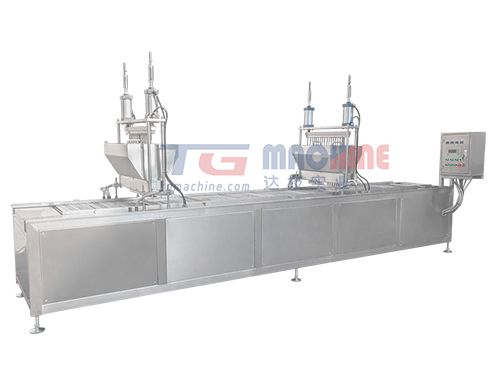

- Marshmallow Production Line

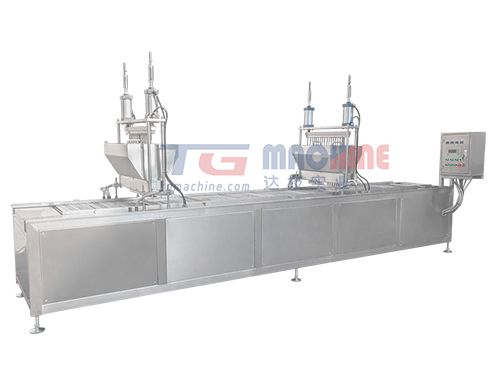

The marshmallow production line is designed to manufacture marshmallows in both a variety of shapes and fillings at a production capacity of up to 500kg/hour. To ensure it meets QS and food hygiene standards, the production line is composed of brushed stainless steel with sensors provided by Siemens to ensure the high sensitivity. Marshmallows can be extruded or deposited according to your requirements. For more information, please do not hesitate to contact us.

-

-

- Toffee Candy Production Line

TG Machine’s toffee candy production line is fully automatic, carrying out all processes from raw material preparation to toffee candy formation to save labor costs. It is used in the production of different toffee candies, including single-color toffee, double-color toffee, filled toffee candies, striped toffee and other toffee types. Our production lines are also customized to fit specific customer factory layouts and special requirements.

-

-

- Snickers Bar Production Line

The snicker bar production line is designed to produce a wide range of candy, including single-layer cracker toffee bars, central-filling milk candy, toffee candy and other candy types. This production line automatically carries out secondary coating processes, thereby significantly improving the production output. With a maximum capacity of 1200kg/hour, it is ideal for large scale candy factories.

The snicker bar production line is designed to carry out heating, concentrating, slurrying, stirring and blending processes. It features a stable operation, neat and consistent formation, as well as an easy to operate and maintain operation and a wide application range.

-

-

- Soft Biscuit Production Line

TG Machine offers a variety of equipment for soft biscuit production lines, designed to meet GMP food hygiene standards and customer requirements regarding different soft biscuit types.

The following are just a few common configurations and we will customize the soft biscuit production line to meet specific customer needs.

-

-

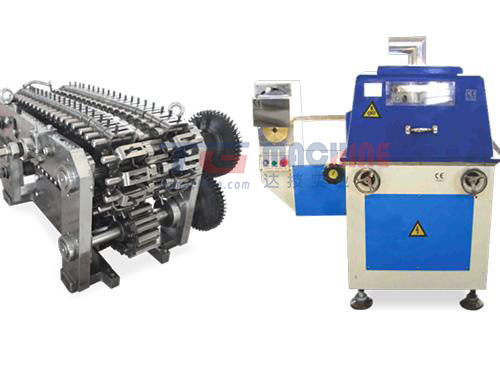

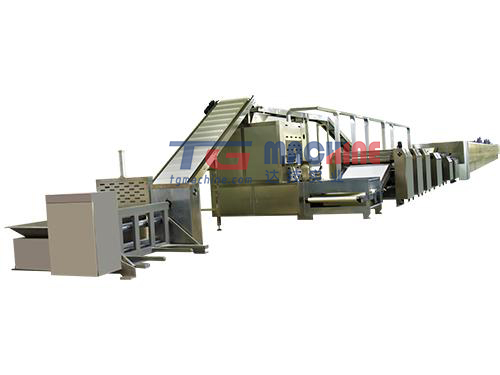

- Hard Biscuit Production Line

TG Machine provides a variety of hard biscuit production lines in different configurations and capacities to meet specific requirements, with a maximum capacity of 1250kg/hour. In addition, we also provide an array of molds for the production of different biscuit shapes.

-

-

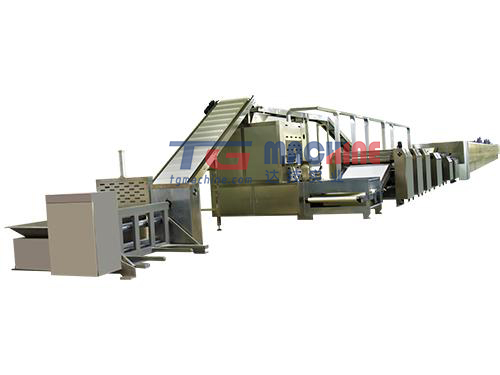

- Multifunction Biscuit Production Line

The multifunctional biscuit production line is designed to produce both hard and soft biscuits. To meet unique customer requirements, TG Machine offers a variety of multifunctional biscuit production lines in different configurations and capacities, with a maximum capacity of 1500kg/hour. In addition, we also offer a variety of biscuit mold shapes for the production of different biscuit shapes.

-

-

- As a professional food machinery manufacturer, TG Machine manufactures a variety of chocolate production lines for customers to choose from for production of regular chocolate, filled chocolates, two-color, double layer chocolate, and other chocolate candy types.

This production line is an automatic, PLC controlled line designed to keep labor costs low.

It comes equipped with a standard 32 pistons to deposit 32 chocolates in one pour. The hole size is adjustable.

-

-

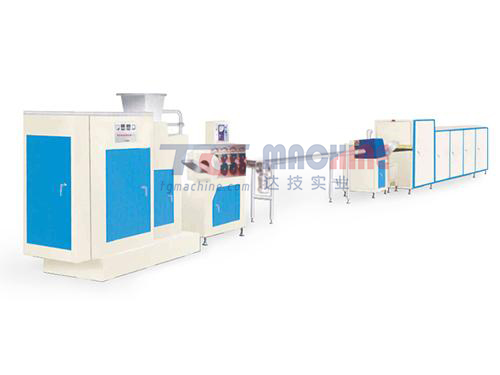

- The T300 central-filled soft chewy candy production line is one of TG Machine’s main products. It was designed and developed in response to market changes and an increase in demand for candy with low sugar, excellent taste, variety and better nutritional value. The technology, mechanical behavior and technical indexes of this chewy candy production line meets advanced international standards for performance and reliability.

-

-

- The KT-10 handmade marshmallow depositing machine uses plastic molds for marshmallow production. It is efficiently controlled with a servo motor and features a z-shaped copper nozzle with an adjustable length and 360° rotation. The deposition distance is also adjustable, ensuring this marshmallow depositing machine is compatible with most plastic molds for handmade marshmallow production.

-

-

- Due to its deliciousness and fun to enjoy, popping boba is rapidly gaining popularity all over the world. The production of popping boba in the local area saves costs and time so has become the choice of many food manufacturers. Here at TG Machine, you can find the right equipment to produce popping boba.