- Home

- Solution

- Candy Production Line

- Marshmallow Production Line

Marshmallow Production Line

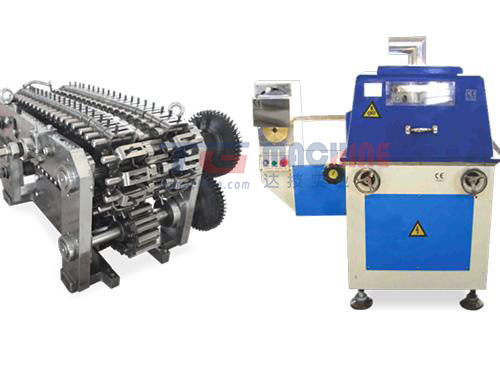

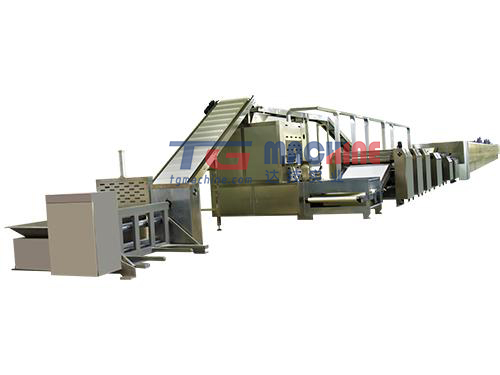

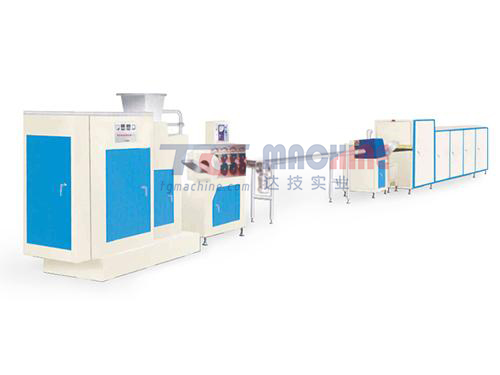

The marshmallow production line is designed to manufacture marshmallows in both a variety of shapes and fillings at a production capacity of up to 500kg/hour. To ensure it meets QS and food hygiene standards, the production line is composed of brushed stainless steel with sensors provided by Siemens to ensure the high sensitivity. Marshmallows can be extruded or deposited according to your requirements. For more information, please do not hesitate to contact us.

Features

- The production line continuously produces marshmallows in a variety of shapes, fillings, and colors.

- The aerating machine operates in a continuous, stable manner.

Standard

Optional

Why you choose TG Machine’s production line?

- Only high-quality materials and parts sourced from trusted brands are used to ensure the reliability and high output of the equipment.

- The high level of automation eliminates the risks posed in manual operation, such as unqualified products and safety concerns.

- Each production line is designed according to the actual layout and operation of your factory so as to meet your special requirements.

- All our production lines are designed and manufactured in a way that meets GMP requirements. They can also meet the quality standards of your country.

Other Production Lines

-

- No.7151, Puwei Road, Huqiao Town, Fengxian District, Shanghai

- Gang Liu

- +86-21-67183392

- +86-13524622057

- inquiry@tgmachine.com

-

- Hard Candy Production Line

- Gummy Candy Production Line

- Sucker Production Line

- Chewy Gum Production Line

- Marshmallow Production Line

- Toffee Candy Production Line

- Snickers Bar Production Line

- Biscuit Production Line

- Chocolate Production Line

- Central-Filled Soft Chewy Candy Production Line

- Handmade Marshmallow Depositing Machine

- Popping boba production line